I am currently working on a proof of concept project to see how easily one can manufacture a fully functional plastic injection molded part. The "ingredients" in this recipe are Rhino 3D, a ZPrinter 3D printer from Z Corporation and a bench-top plastic injection machine from Galomb.

I am currently working on a proof of concept project to see how easily one can manufacture a fully functional plastic injection molded part. The "ingredients" in this recipe are Rhino 3D, a ZPrinter 3D printer from Z Corporation and a bench-top plastic injection machine from Galomb.

A key element in this application is the fact that prototypes created with the ZPrinter are made of Gypsum which makes them resistant to much higher temperatures than plastic-made parts - thus making it suitable as material for molds.

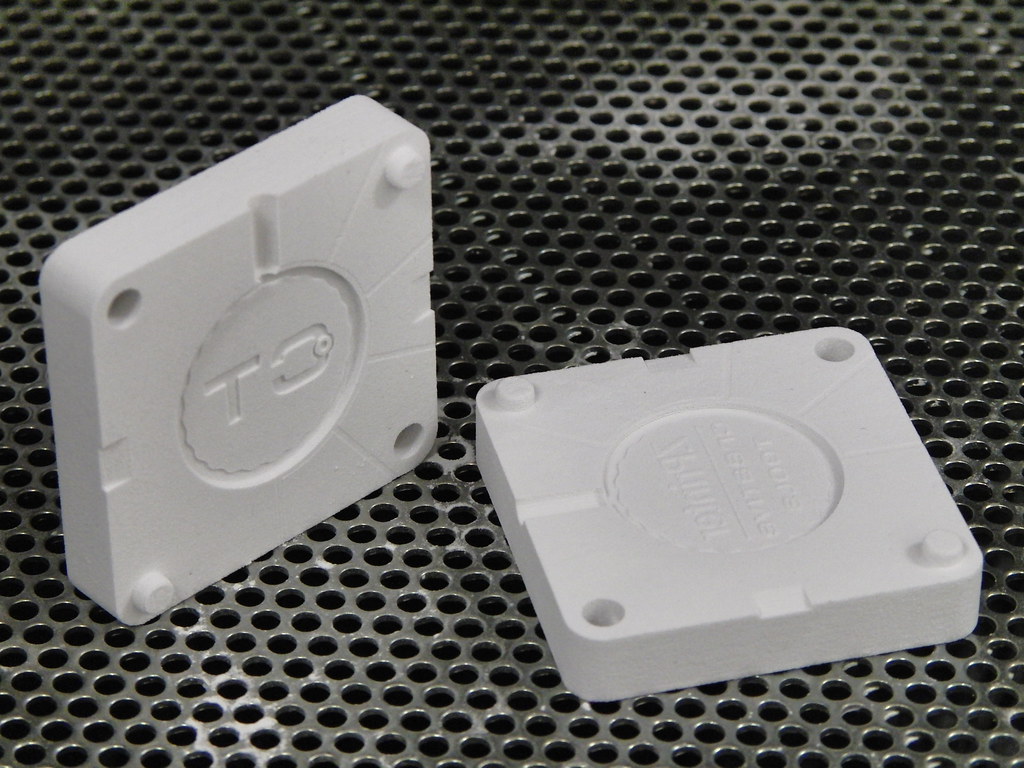

As a sample part for this project I chose to quickly and easily model in Rhino 3D a simple coin with our logo on it. Then I created the volume for the mold as well as channels for plastic and air flow. A quick Boolean Difference operation made the mold complete.

I want to point out that it is very nice and practical to have the Z Corporation native file format built-in into Rhino 3D. Naturally one can always save to STL and then open it up in the ZPrint-software. But it makes life easier to just choose File > Print 3-D > Z Corp Print, right from within Rhino's File-menu.

The mold was then 3D printed on the ZPrinter and hardened with common CA glue. We also did a test with Epoxy but found the CA-method to be much faster and held up nicely when the mold was compressed and used.

The mold was then 3D printed on the ZPrinter and hardened with common CA glue. We also did a test with Epoxy but found the CA-method to be much faster and held up nicely when the mold was compressed and used.

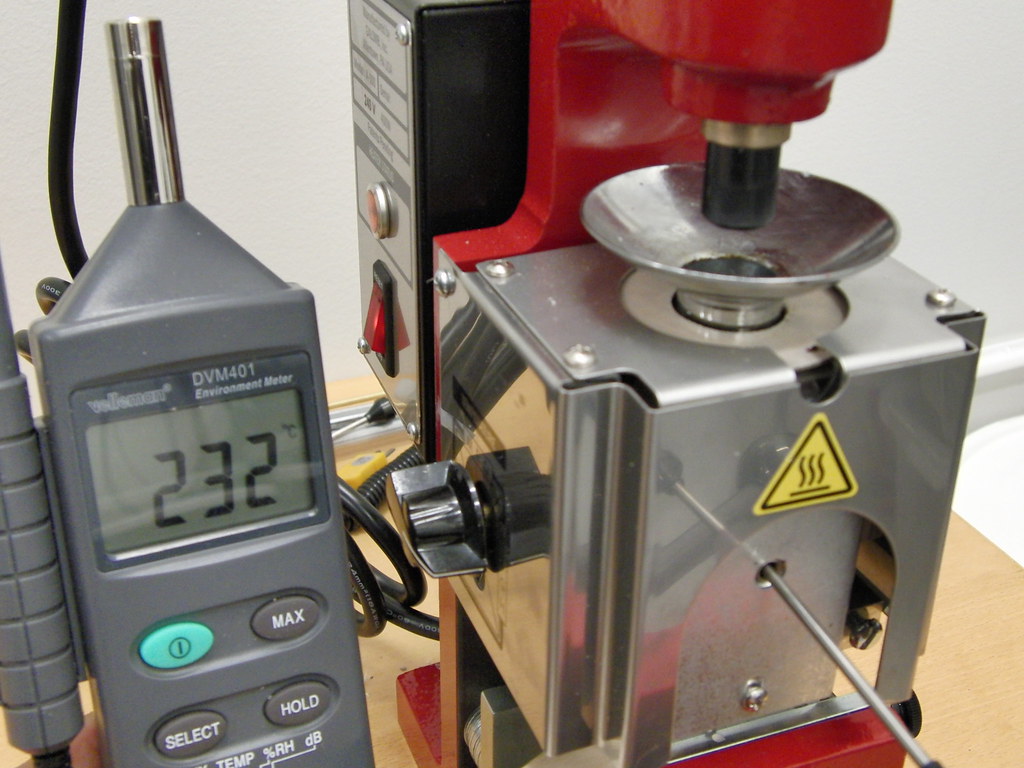

Shortly after the CA-glue had hardened I could start making plastic coins with the Galomb injection molding machine. This is where the fun really starts! Naturally I could use standard plastic pellets as used in industrial manufacturing. Instead it was much cooler to recycle old plastic parts and containers I found lying around in our office. The grey coloured coin is by the way made of a discarded empty binder cassette from the actual ZPrinter. Talk about recycling! :)

Shortly after the CA-glue had hardened I could start making plastic coins with the Galomb injection molding machine. This is where the fun really starts! Naturally I could use standard plastic pellets as used in industrial manufacturing. Instead it was much cooler to recycle old plastic parts and containers I found lying around in our office. The grey coloured coin is by the way made of a discarded empty binder cassette from the actual ZPrinter. Talk about recycling! :)

Above you can see the very first and second coin being made of red plastic.

My conclusion is that this gave us a very nice and satisfactory result. All the work, from idea and CAD-work in Rhino 3D all the way to the plastic injection molding, was made in less than one day! In comparison one would have to create a metal mold with a CNC milling machine, which takes much more time and is quite expensive.

As a logical part of this prototype manufacturing process the ZPrinter now has two functions - one is to quickly and inexpensively make a positive model of the Rhino 3D file, and the other is to create the mold for plastic injection from the same file.

So far we have molded 30+ coins and the mold is still going strong! :-)

For a complete image slide show of this process as well as more videos please check out the following URL.

We will continue this project and refine all the techniques as well as share them with anyone who wants to know more about it. Please feel free to get in touch with me.

/Paulo Kiefe

Comment

-

Comment by Paulo Kiefe on January 16, 2012 at 6:00pm

-

I am glad you liked it. :)

-

Comment by John P. Niebergall on January 15, 2012 at 10:52pm

-

This is a cool idea, thanks for sharing

© 2025 Created by Andres Gonzalez.

Powered by

![]()

You need to be a member of RhinoFabStudio to add comments!

Join RhinoFabStudio